Operating a cold storage store presents differences in processes compared to traditional warehousing when it highly demands specialised knowledge, management expertise, and substantial investments. Through this article, Savills Industrial will provide expert guidance to help you understand the operations of cold storage and find reliable providers.

The cold storage operation process includes many steps to ensure efficient, stable and safe operation, including:

This is crucial when commencing operations of a new cold storage facility or reactivating one after a prolonged period of inactivity. The following procedures are required for system inspection:

– Open all shut-off valves on the liquid return line, liquid supply line, hot gas supply line, and defrost water drain line

– Turn off the liquid supply and defrost switches at the evaporators

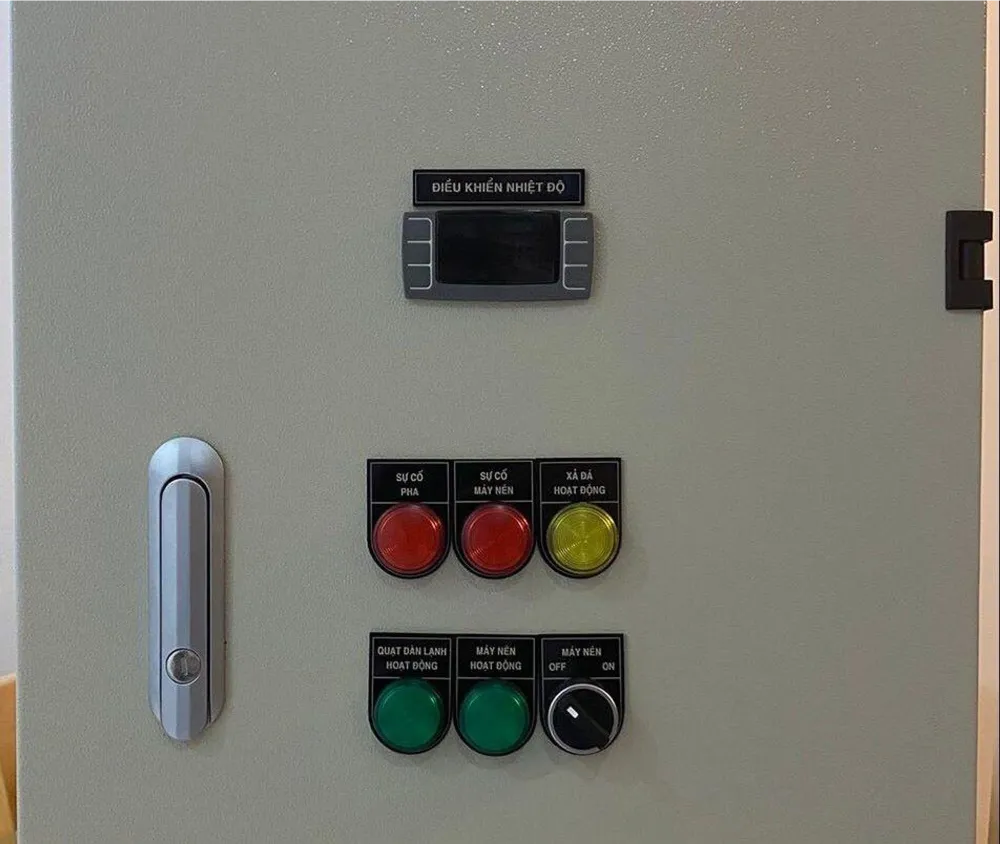

– Switch on all circuit breakers for the power supply, evaporators, and control power

A cold storage operator must thoroughly inspect and ensure that the compressor is working. In case the compressor is liquid-pump driven, it should be assured that this component is functioning. During this step, two essential actions are required:

– Turn on the switch to activate the compressor and evaporators.

– The indicator light for the compressor must be turned on and activated in suction mode.

Cooling preparation process before transporting products into the warehouse

This step requires careful execution with the following considerations to ensure safe and effective operation of the cold storage.

– Goods stored in warehouses should not be stacked higher than the evaporators and must not obstruct the airflow within the storage

– Ensure safety during loading and unloading goods process

– Ensure the aisles’ width while arranging goods to allow operators to easily move

– Goods should not be placed beneath or behind the evaporators

– A small cold warehouse should be aware of transferring goods within the warehouse. This should be carried out promptly, and it is recommended to install thermal or air curtains to enhance efficiency and facilitate smooth operations

Goods in cold storage should be scientifically arranged with adequate ventilation

This step simply requires turning the defrost switch to “ON” mode and switching it back to “OFF” once the defrosting process is complete. However, while defrosting, the following requirements must be adhered:

– Regularly check the level of frost/ice buildup on the evaporator coils and take timely measures to defrost/de-ice

– Warehouses with multiple evaporators should defrost each unit individually rather than all at once to minimise temperature loss within the warehouse

– It should be ensured that all frost/ ice is completely defrosted

Make sure to defrost the frost/ice regularly while operating cold storage

Cleaning is important when operating cold storage to ensure the stability and efficiency of warehouse’s operation. A low-pressure water spray is the preferred method for cleaning panels, as it effectively removes dirt and grime without damaging the surfaces. The cleaning process involves the following steps:

– Shut down the refrigeration unit

– Apply a water spray

– Apply cleaning agent

– Rinse off the cleaning agent with water

– Apply a disinfectant

– Rinse the panel with water

– Dry the panel surface

Cold storage cleaning operations must adhere to proper technical procedures

There will be some cases where cold storage facilities are not in use for extended periods. Therefore, proper maintenance is required to prevent the damage and prolong its lifespan. The maintenance steps to be taken are as follows:

– De-energise the warehouse

– Conduct a thorough cleaning of the cold storage unit

– Ventilate the warehouse by opening all doors

– Carry out routine maintenance on the refrigeration system

Cold storage facilities with periods of non-use must be properly maintained

It is important to keep the following points in mind when operating a cold storage to ensure maximum preservation efficiency, safety, and cost-effectiveness.

– Maintaining the appropriate temperature for the specific type of goods stored to preserve product quality and minimise the risk of damage within the cold storage facility

– Prevent moisture or high humidity from accumulating to maintain product quality and prevent mold growth

– Worker safety should be prioritised by implementing a rotational shift system, which can help minimise the adverse health effects of prolonged exposure to freezing temperatures

– Strictly controlling information on incoming and outgoing goods, including product name, entry/exit times, and labels, is essential to prevent product backlog and streamline order processing

– A segregated entry and exit system should be designed to minimise heat loss within the facility

– Automation systems should be considered for cold storage operations to reduce labor costs and optimise operational performance

– Consider implementing supplementary freezing equipment to reduce product loss and enhance the profitability of cold storage operations

– Preparing strategy shortening the transportation time since the further the distance, the higher the risk of heat loss that directly affects good’s quality

– A contingency plan is essential to minimise losses from unexpected incidents

– Regularly updating cold warehouse’s operational status to deliver the optimal management and development solutions

Key points to remember when operating cold storage

For professional and efficient cold storage operations, the design of the warehouse system must adhere to the following critical guidelines:

– Maximise storage space to reduce costs and improve efficiency

– The design should ensure the continuous balance of factors, including temperature, airflow and humidity

– Prioritise utilising high-performance insulation materials to ensure a stable temperature within the storage facility

– Ensure electrical and hydraulic safety to protect both personnel and stored goods

– The cold storage ventilation system must be scientifically designed, consistent, and have efficient airflow

– Providing workers with complete protective gear, such as clothing, gloves, and boots, to safeguard their health while working in the low temperature environment

– Utilising advanced technologies to further enhance cold storage operational efficiency, cut management costs, and promote environmental sustainability

– Clearly define the specific requirements of each product to tailor humidity, temperature, and other storage conditions accordingly

Strict adherence to cold storage design regulations is necessary to ensure product quality and worker safety

It is crucial to maintain the best quality and safety of all goods stored in cold storage. Discover the detailed warehouse operation process to learn about a comprehensive management system for your business.

Savills Industrial strictly adheres to standard cold storage operation procedures

With years of experience, Savills Industrial is confident of being a trusted partner for professional warehouse management and operation services. Call us at 0986.718.337 for expert advice and tailored solutions to optimise your storage operations.